Among the numerous engineering plastics in modern industry, Polyoxymethylene (POM) stands out for its excellent comprehensive properties. It not only possesses high strength, high rigidity, and excellent wear resistance, but also excels in chemical corrosion resistance and dimensional stability. So, how exactly does Polyoxymethylene resin take the lead among so many materials?

It is precisely because of these unique advantages of Polyoxymethylene resin that it demonstrates its irreplaceable value, from precision parts in automobiles to wear-resistant components in electronic products, and high-strength gears in industrial machinery. However, in addition to these known application areas, are there other potential applications for Polyoxymethylene resin? And what will be its future development trends?

What performance characteristics make Polyoxymethylene resin stand out?

Polyoxymethylene (POM) resin, as a high-performance engineering plastic, occupies an important position in many fields due to its excellent comprehensive properties. Its characteristics such as high strength, high rigidity, wear resistance, and chemical corrosion resistance make it an ideal choice for replacing traditional metal materials.

- Excellent Mechanical Properties: Polyoxymethylene resin possesses high strength, high rigidity, and excellent wear resistance.

- Excellent Environmental Resistance: Polyoxymethylene resin has good chemical corrosion resistance and low water absorption.

- Good Processing Performance: Polyoxymethylene resin is easy to process and mold, and has good dimensional stability.

- Other Properties: Polyoxymethylene resin has good electrical insulation and elastic resilience.

How do these features translate into product applications?

The excellent properties of Polyoxymethylene resin are not just theoretical, but are realistically translated into innovative applications in various fields. From precision components in the automotive industry to wear-resistant components in electronic devices, and safety guarantees in medical devices, Polyoxymethylene resin shines in different industries due to its unique advantages.

- Automotive Industry: Polyoxymethylene resin is used to manufacture precision components, as well as interior and exterior parts, for automobiles.

- Electronics and Appliances: In the electronics and appliances field, Polyoxymethylene resin is used to produce connectors, switches, as well as housings and structural components.

- Industrial Machinery: Polyoxymethylene resin is applied in industrial machinery to manufacture gears, bearings, conveyor belts, and components for conveying systems.

- Medical Devices: Polyoxymethylene resin, possessing biocompatibility, is used to manufacture medical device components and drug delivery devices.

What are the advantages and disadvantages of Polyoxymethylene resin?

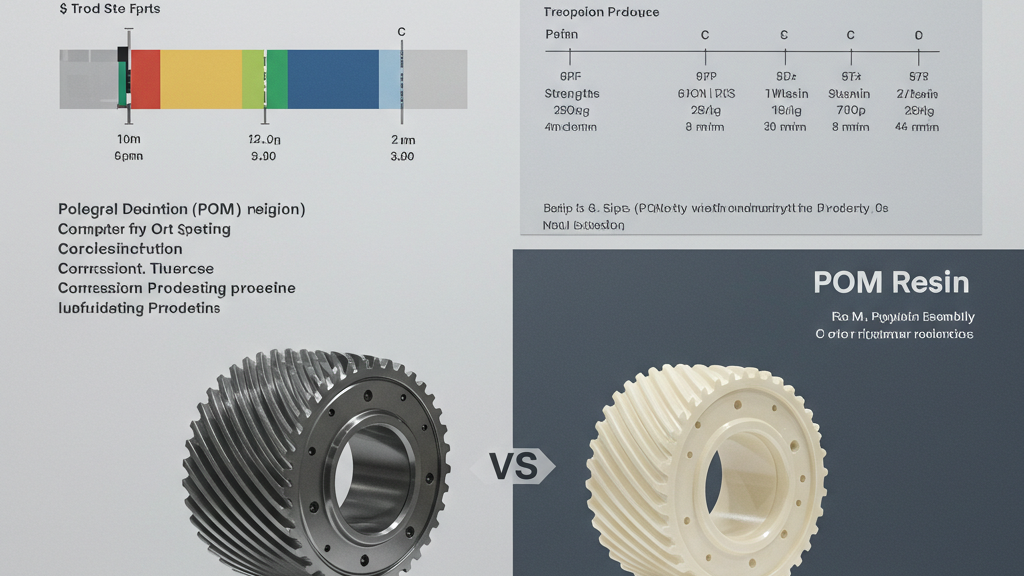

Metal materials and Polyoxymethylene resin each have their own merits. Metal materials are known for their high strength and high-temperature resistance, while Polyoxymethylene resin stands out for its lightweight properties, corrosion resistance, and ease of processing. So, in practical applications, how should we weigh the pros and cons of these two materials to make the optimal choice?

- Lightweight: Polyoxymethylene resin has significant advantages in lightweight applications.

- Corrosion Resistance: Polyoxymethylene resin exhibits excellent corrosion resistance in harsh environments.

- Easy to Process: Polyoxymethylene resin reduces production costs through efficient processing techniques.

- Self-Lubricating: The self-lubricating properties of Polyoxymethylene resin reduce maintenance needs.

Performance comparative analysis

|

Performance Characteristic |

POM (Polyoxymethylene) |

Steel |

Aluminum |

Titanium |

| Lightweight | Significant Advantage | Disadvantage | Advantage | Advantage |

| Corrosion Resistance | Excellent | Disadvantage | Moderate | Excellent |

| Machinability | High Efficiency, Low Cost | Disadvantage | Moderate | Disadvantage |

| Strength/Rigidity | Relatively Low | Excellent | Moderate | Excellent |

Development Trends of Polyoxymethylene Resin

The development of Polyoxymethylene resin will revolve around high performance and functionalization to meet growing industrial demands. Meanwhile, lightweighting and environmental friendliness are important trends in the automotive and sustainable development fields.

1.High Performance: Polyoxymethylene resin will evolve toward higher strength and heat resistance.

2.Functionalization: Polyoxymethylene resin will be endowed with more functional properties, expanding its application scope.

3.Lightweighting: Polyoxymethylene resin will achieve further lightweighting in areas such as the automotive industry.

4.Environmental Friendliness: The development of environmentally friendly Polyoxymethylene resin is an important direction for development.

Conclusion

In the future, the development of POM will revolve around high performance, functionalization, lightweighting, and environmental protection. Through technological innovation, POM will possess higher strength, more functions, and a lighter weight to meet the ever-increasing industrial demands.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Apr-02-2025